Piston gasi compressors (inodzorera compressors) yave yakakosha midziyo mukumanikidza gasi mumaindasitiri nekuda kwekubuda-kudzvanywa kwayo, kuchinjika kutonga, uye kuvimbika kwakasiyana. Ichi chinyorwa chinotsanangura zvine hungwaru pane yavo tekinoroji mabhenefiti mune akawanda-mhando gasi compression mamiriro, zvichibva pane zvimiro zvekugadzira misimboti.

I. Core Structural Design

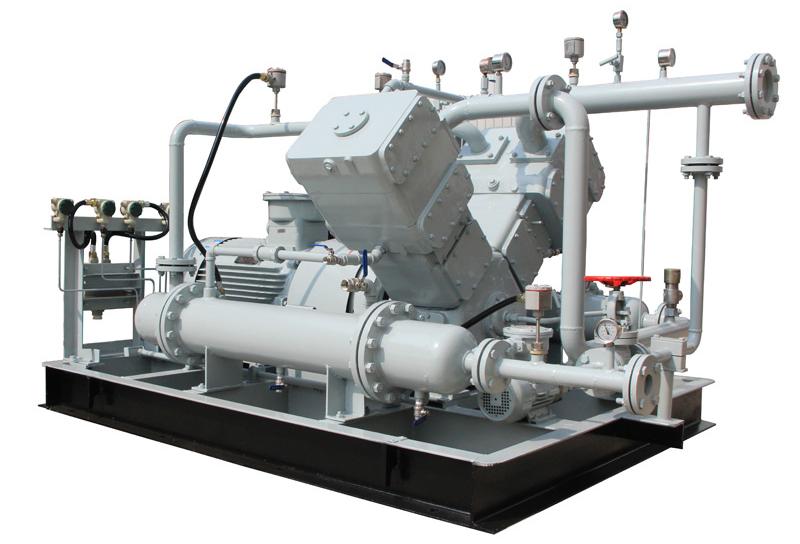

Kuita kwepiston gasi compressors kunobva kune yakanyatso kurongeka chikamu system, kusanganisira zvinotevera zvikamu zvakakosha:

1. High-Simba Cylinder Assembly

Yakagadzirwa kubva kusimbi yakakandwa, alloy simbi, kana hunyanzvi hwekunamira zvinhu kuti zvikwanise kumira kwenguva refu kubva kune hukasha media senge acidic magasi (semuenzaniso, H₂S) uye high-pressure oxygen.

Yakabatanidzwa mvura/oiri yekutonhodza nzira kuti inyatso gadzirisa tembiricha inoshanduka inokonzerwa negasi zvinhu (semuenzaniso, yakaderera viscosity yehydrogen, yakakwirira reactivity yeammonia).

2. Multi-Material Piston Assembly

Piston Korona: Kusarudzwa kwezvinhu zvakagadzirirwa kumakemikari egasi - semuenzaniso, 316L simbi isina simbi yesarufa-ine gasi rinopesana nekuora, machira eceramic ekupisa kwepamusoro CO₂ nharaunda.

Kuvhara Mhete Sisitimu: Inoshandisa graphite, PTFE, kana simbi inoumbwa zvisimbiso kudzivirira kubuda kwemagasi akanyanya-kumanikidza (semuenzaniso, helium, methane), kuve nechokwadi chekudzvanya ≥92%.

3. Intelligent Valve System

Nesimba rinogadzirisa nguva yevharuvhu yekutora/kupedza nekusimudza kuti igone kugarisana nekuwanda kwegasi uye kumanikidzana (semuenzaniso, nitrogen pa1.5:1 kuenda kuhydrogen pa15:1).

Mahwendefa evharuvhu asingaite kuneta anoshingirira kuchovha bhasikoro (≥1,200 mabhasikoro/miniti), achiwedzera nguva dzekugadzirisa munzvimbo dzinopisa/zvinoputika.

4. Modular Compression Unit

Inotsigira inochinjika 2- kusvika 6-nhanho yekumanikidza masisitimu, ine imwe-nhanho kudzvanywa kusvika ku40-250 bar, inosangana nezvinodiwa zvakasiyana kubva kune inert gasi kuchengetedza (semuenzaniso, argon) kune syngas kudzvanywa (semuenzaniso, CO + H₂).

Kurumidza-kubatanidza nzvimbo dzekubatanidza dzinogonesa kukurumidza kutonhora masisitimu kugadziridzwa kunoenderana nerudzi rwegasi (semuenzaniso, kutonhora kwemvura yeacetylene, kutonhora kwemafuta eFreon).

II. Industrial Gasi Kuenderana Zvakanakira

1. Full Media Compatibility

Corrosive Gases: Zvishandiso zvakanatsiridzwa (semuenzaniso, Hastelloy cylinders, titanium alloy piston rods) uye kuomeswa kwepasi kunopa kusimba munzvimbo dzakapfuma sesarufa- uye halogen.

Yakakwirira-Kunatswa Magesi: Mafuta-asina mafuta ekuzora uye ekupedzisira-chaiyo kusefa kuwana ISO 8573-1 Kirasi 0 kuchena kwemagetsi-giredhi nitrogen uye okisijeni yekurapa.

Anopisa / Anoputika Magasi: Inoenderana neATEX/IECEx certification, ine spark kudzvanya uye kudzvanya kuchinjika madhamu ekubata zvakachengeteka kwehydrogen, okisijeni, CNG, uye LPG.

2. Adaptive Operational Capabilities

Wide Flow Range: Variable-frequency drives uye clearance volume adjustment inogonesa linear flow control (30% -100%), inokodzera kugadzirwa kwepakati (semuenzaniso, makemikari chirimwa exhaust recovery) uye kuenderera mberi kwekupa (semuenzaniso, mhepo yekuparadzanisa zvikamu).

Smart Kudzora: Yakabatanidzwa gasi kuumbwa sensors auto-adjust parameters (semuenzaniso, tembiricha zvikumbaridzo, lubrication mitengo) kudzivirira kusashanda kunokonzerwa nekukasira kushanduka gasi pfuma.

3. Lifecycle Cost Efficiency

Yakaderera Maintenance Dhizaini: Yakakosha chikamu hupenyu hurefu hwakawedzerwa ne> 50% (semuenzaniso, 100,000-awa crankshaft kugadzirisa nguva), kuderedza nguva yekudzikira munzvimbo dzine njodzi.

Energy Optimization: Kudzvanya macurves akagadzirirwa gasi-specific adiabatic indices (k-values) anowana 15% -30% ekuchengetedza simba zvichienzaniswa neakajairika mhando. Mienzaniso inosanganisira:

Mhepo yakadzvanywa: Simba chairo ≤5.2 kW/(m³/min)

Kuwedzera gasi rechisikigo: Isothermal kunyatsoita ≥75%

III. Key Industrial Applications

1. Standard Industrial Gases (Oxygen/Nitrogen/Argon)

Mukugadzirwa kwesimbi uye semiconductor, madhizaini asina mafuta ane mamorekuru sieve post-kurapa anovimbisa 99.999% kuchena kwezvishandiso zvakaita sesimbi yakanyungudutswa inodzivirira uye kugadzirwa kwewafer.

2. Magesi Emagetsi (Hydrogen/Syngas)

Multi-stage compression (inosvika 300 bar) yakasanganiswa nekuputika kudzvinyirira masisitimu inobata zvakachengeteka haidrojeni nekabhoni monoxide mukuchengetedza simba uye makemikari synthesis.

3. Magasi Anoparadza (CO₂/H₂S)

Zvigadziriso zvinodzivirira kuora zvakagadzirirwa- semuenzaniso, tungsten carbide coatings uye mafuta anodzivirira asidhi-anogadzirisa hupfumi hwesarufa, hunyoro hwepamusoro mukujoinwazve muoiri uye kutora kabhoni.

4. Specialty Electronic Gases (Fluorinated Compounds)

Kuvakwa kwakazara-chisimbiso uye helium mass-spectrometer leak yekuona (leak rate <1×10⁻⁶ Pa·m³/s) inovimbisa kubata kwakachengeteka kwemagasi ane ngozi setungsten hexafluoride (WF₆) uye nitrogen trifluoride (NF₃) mu photovoltaic uye IC industries.

IV. Innovative Technological Advancements

Digital Twin Systems: Real-time data modeling inofanotaura kupfeka piston mhete uye kukundikana kwevharuvhu, zvichiita kuti zviyeuchidzo zvekugadzirisa 3-6 mwedzi isati yasvika.

Kubatanidzwa kweGreen Process: Kurasa kupisa kudzoreredza zvikamu zvinoshandura 70% yekumanikidza kupisa kuita chiutsi kana magetsi, zvichitsigira kabhoni kusarerekera kune kwazvakarerekera.

Ultra-High-Pressure Breakthroughs: Pre-stressed winding cylinder tekinoroji inowana imwe-nhanho compression> 600 bar mumalabhu marongero, ichigadzira nzira yeramangwana hydrogen kuchengetedza uye kutakura.

Mhedziso

Piston gasi compressors, ine modular dhizaini uye kugona kugadzirisa, unza mhinduro dzakavimbika dzekugadzira gasi reindasitiri. Kubva pakudzvanyirirwa kusvika kune yakanyanyisa-mamiriro ehunyanzvi hwekubata gasi, zvimiro zvekugadzirisa zvinovimbisa kuchengetedza, kushanda zvakanaka, uye kusingadhuri.

Kuti uwane madhairekitori ekusarudza kwecompressor kana tekinoroji yekusimbisa mishumo yakagadzirirwa kune chaiyo gasi midhiya, ndapota taura neinjiniya timu yedu.

Technical Notes:

Dhata yakatorwa kubva kuISO 1217, API 618, uye mamwe epasi rose ekuyedza zviyero.

Kuita chaiko kunogona kusiyana zvishoma zvichienderana nekuumbwa kwegasi uye nemamiriro ekunze.

Zvigadziriso zvezvishandiso zvinofanirwa kuenderana nemirairo yekuchengetedza yenzvimbo yemidziyo yakakosha.

Nguva yekutumira: May-10-2025